GEAR

designed to meet the heavy duty Typical Physical Characterists demands of a variety of industrial gear applications including those operating under such severe conditions as critical sliding velocities and shock loading that may occur under certain loading situations

GEAR COMP EP – ISO 150, 220, 460

GEAR COMPOUNDS are designed to meet the heavy duty Typical Physical Characterists demands of a variety of industrial gear applications including those operating under such severe conditions as critical sliding velocities and shock loading that may occur under certain loading situations. They are created from high quality base oilswith the perfect additive package to provide the best combination of performance properties, such as extreme pressure andoxidation resistance, required in difficult industrial applications.

Customer Benefits

• Help maintain clean gear and bearing surfaces, minimizing deposits which interfere with effective lubrication.

• Effective EP system minimizes wear rates and maintains efficient transfer of power. Good water separation andeffective rust inhibitors protect surfaces against rust and corrosion. High thermal stability additive system minimizes the formation of high temperature compounds which can be corrosive to bearing materials.

• Minimize oil oxidation, limiting viscosity increase and promoting long drain intervals.

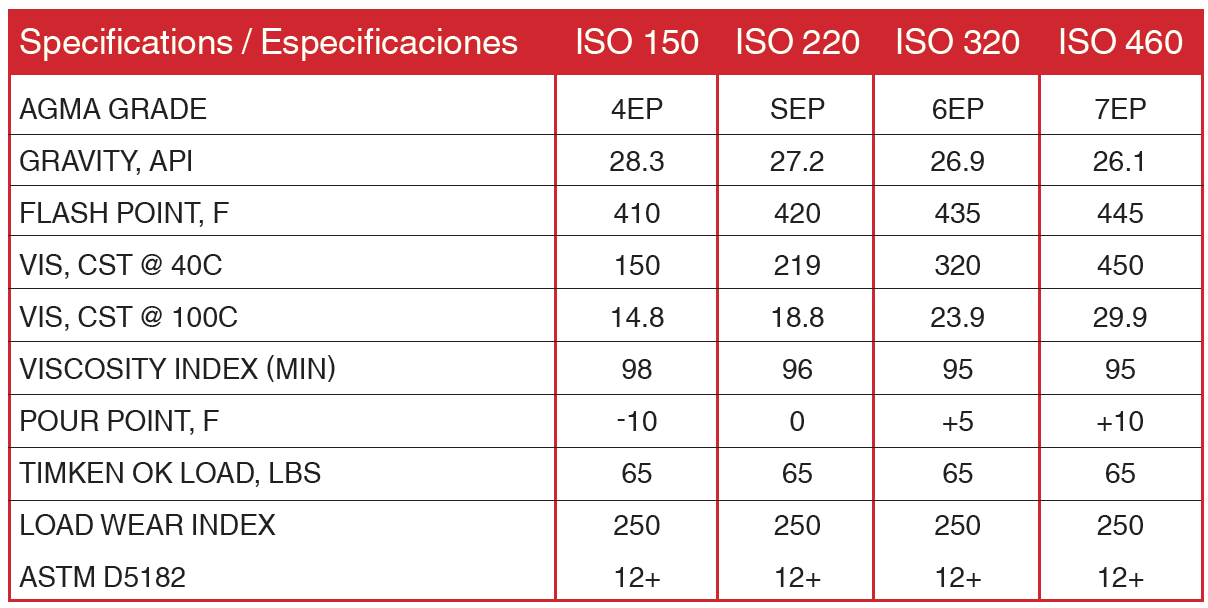

INDUSTRIAL GEAR FLUID – ISO 150, 220, 320, 460

INDUSTRIAL GEAR FLUID are multipurpose industrial gear Typical Physical Characterists lubricants made with highly paraffinic base stocks and modern performance additives.

Provide extreme pressure protection as well as anti-wear protection. Offersuperior rust and oxidation control, corrosion control and demulsibility. Have high load carrying capacity, separate quickly from water and are exceptionally stable over a wide range of temperatures.

INDUSTRIAL GEAR FLUID are intended for use in enclosed gear drives and wherever an AGMA extreme pressure lubricant is required. INDUSTRIAL GEAR F meet or exceed the following specifications: U.S. Steel 224, AGMA 250.04 and 9005 and Cincinnati Milacron.

Customer Benefits

• Excellent oxidation and thermal stability

• Effective corrosion Inhibition

• Outstanding load carrying and anti-frictioncharacteristics

• Wide range of viscosities

• Resistant to micro-pitting

• Water shedding properties

• Load Carrying Capacity

• Lead-free

• Extreme Pressure Properties

Contact Us

Terms and Product Warranty

Terms and Product Warranty

Terms: Ex Works: Everlast Lubricants USA, assumes No responsibilities after the product has left our

warehouse/possession for any Loss, Damages or claims. Customer can inspect prior to / while product is loaded into the container or truck customer selects. Customer is responsible for getting product to destination and documentation. Everlast Lubricants USA supply Invoice, Seal, Pieces and Approximate Weight.

Product Warranty: Everlast Lubricants USA Warranty product Prior to shipping. Customer can if they so select test product prior to shipment in an approved Laboratory with signed sealed samples. All products meet and are what is on the label. Once Product has left Everlast Lubricants USA possession, Everlast Lubricants USA is Not responsible or warrant product from damage or quality after product leaves our possession.